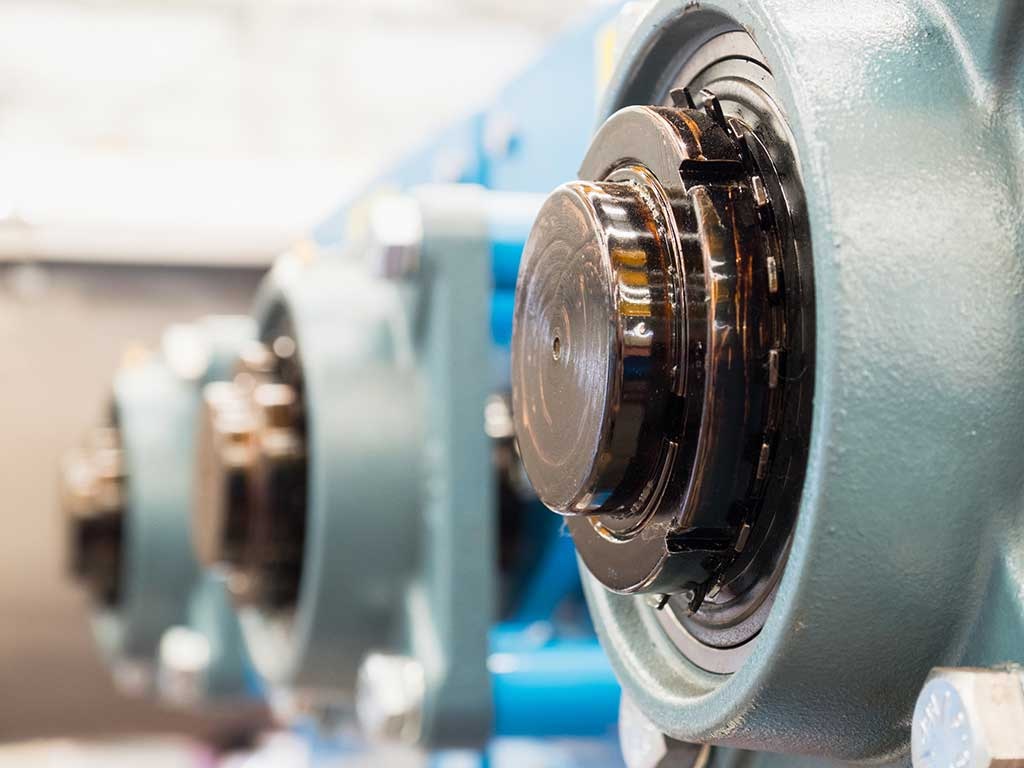

Motors and Bearings Industry

High and low temperature, high speed, heavy load, long life lubrication solutions

Customized Products

Designed for your applications

As a leading grease brand and manufacturer, we understand the importance of bearing lubrication in mechanical engineering. Whether it’s in rolling bearings, plain bearings or linear guide bearings, we are committed to providing superior lubrication solutions to ensure that your mechanical equipment runs smoothly at high speeds, extends service life and reduces maintenance costs.

In our product line, we have lubricants and greases to meet the needs of different types of bearings. Not only that, but we also offer specialised bearing lubricants, bearing greases and dry film lubrication products for a wide range of different operating conditions. Whether your bearings operate at high temperatures, high pressures, high speeds or in extreme environments, we have a lubrication solution for you.

High Speed or Heavy Load

We improve the safety of your operations

Heavy-duty lubricating greases play a crucial role in various industrial applications, offering exceptional performance to cope with extreme working conditions and highly loaded environments. Under high-load conditions, these greases must be able to remain stably on the working surfaces without being squeezed out or forced into bearing clearances.

Typically, these greases exhibit excellent adhesion, effectively adhering to metal surfaces to provide long-lasting lubrication. Furthermore, they can maintain stability at high temperatures, without premature decomposition or failure, thereby preserving their lubrication performance.

Multi-purpose greases are generally not suitable for high-speed bearings because the base oil viscosity may be too high or the grease may be agitated in the raceways, both of which can generate excessive heat. Overheated grease may become too thin and leak from the bearing.

Whether Hot or Cold

Always the right lubricant

until over

NLGI classes

000 – 3

Kinematic viscosities

Certificates

ISO 9001

Registrations

H1, H2, 3H

Low Noise or Water Resistance

Or chemical resistant

Precision bearings use more and more demanding conditions, the bearing noise also has higher requirements, the requirements of the equipment can be maintained for a long time in a stable state of operation, will not be due to lubrication film rupture, resulting in friction and metal surface friction coefficient of direct contact, the friction coefficient increases abruptly, resulting in high-frequency vibration, and even dry friction state, thus generating whistling sound.

Water pollution is one of the important factors causing early failure of bearings, but also an important source of rust and corrosion of equipment, especially in the iron and steel metallurgy industry, mining, shipping, offshore platforms, agricultural machinery, construction machinery and so on.

Not yet found the right solution?

Call us: +86 400 9205357

We will provide the right solution for you